Solid Carbide Tools

High-performance solid carbide tools for demanding applications

What Are Carbide Drills?

Carbide Drills are cutting tools used for creating holes in various materials through a drilling process. Carbide is a composite material consisting of tungsten carbide particles and a binder metal, typically cobalt. Carbide drills are highly favored in machining due to their hardness, wear resistance, and ability to maintain sharp cutting edges even at high temperatures.

Features

- Premium Material: high-quality carbide for exceptional durability and extended tool life

- Precision Drilling: advanced design for accurate, clean holes in various materials

- Efficient Chip Removal: optimized geometry for smooth chip evacuation, minimizing tool wear

Why Choose Carbide Drills From Us

- Boost Productivity: achieve faster drilling speeds and enhanced efficiency

- Cost-Effective: durable tools reduce the frequency of replacements

- Consistent Quality: dependable results for your most critical projects

Applications

- Automotive

- Aerospace

- Medical

- General Engineering

Supported Brands

Related Products

Inquire Now

Experience the superior precision and durability of Carbide Drills from Atek Precision Tools.

Contact us now using the Contact form or phone number below to learn more and optimize your machining operations.

What Are Carbide End Mills?

Carbide End Mills are cutting tools used in milling, where the material is removed from a workpiece using rotary cutters. Carbide End Mills are highly preferred in machining due to their hardness, wear resistance, and ability to maintain sharp cutting edges even at high temperatures.

Features

- Longer tool life: lasts significantly longer than traditional high-speed steel (HSS) end mills, resulting in reduced tool replacement costs and downtime

- Increased productivity: the durability and wear resistance of carbide end mills allow for higher cutting speeds and feed rates, leading to faster machining processes

- Improved surface finish: produces smoother surface finishes on workpieces due to their ability to maintain sharp cutting edges

- Reduced machining time: with their high cutting speeds and feed rates, carbide end mills can help shorten overall machining cycle times

- Enhanced machining capabilities: enables the machining of hard materials such as hardened steels, stainless steels, and exotic alloys with greater efficiency and precision

Why Choose Carbide End Mills From Us

- Superior quality: manufactured to the highest standards, ensuring consistent performance, precision, and durability

- Extensive selection: we offer a wide range of carbide end mills in various shapes, sizes, and configurations to meet the diverse needs of our customers’ machining applications

- Customization options: these can be customized to specific customer requirements, including special coatings, geometries, and lengths, providing tailored solutions for unique machining challenges

- Competitive pricing: we offer competitive pricing on our carbide end mills without compromising on quality, providing excellent value for our customers’ machining operations

Applications

- Automotive

- Aerospace

- Mold Making

- General Machining

Supported Brands

Related Products

Inquire Now

Experience the superior precision and durability of Carbide End Mills from Atek Precision Tools.

Contact us now using the Contact form or phone number below to learn more and optimize your machining operations.

What Are Carbide Reamers?

Carbide Reamers are used in machining to improve the accuracy and finish of drilled holes. Common types include straight-fluted reamers, spiral-fluted reamers, and chucking reamers. The choice of carbide reamer depends on factors such as the material being reamed, hole diameter, tolerance requirements, and surface finish specifications.

Features

- Hardness: carbide reamers are extremely hard, providing excellent wear resistance and maintaining sharp cutting edges for prolonged use

- Precision: manufactured with tight tolerances, carbide reamers ensure consistent and accurate hole dimensions, improving part quality and fit

- Versatility: available in various designs and configurations to accommodate different reaming tasks, materials, and machining conditions

- Heat resistance: enables the reamers to withstand high temperatures generated during the reaming process, reducing the risk of tool failure or deformation

Why Choose Carbide Reamers From Us

- Superior quality: manufactured to the highest standards, ensuring consistent performance, precision, and durability

- Extensive selection: we offer a wide range of carbide reamers in various shapes, sizes, and configurations to meet the diverse needs of our customers’ machining applications

- Customization options: these can be customized to specific customer requirements, including special coatings, geometries, and lengths, providing tailored solutions for unique machining challenges

- Competitive pricing: we offer competitive pricing on our carbide reamers without compromising on quality, providing excellent value for our customers’ machining operations

Applications

- Automotive

- Aerospace

- Mold Making

- Precision Machining

Supported Brands

Related Products

Inquire Now

Experience the superior precision and durability of Carbide Reamers from Atek Precision Tools.

Contact us now using the Contact form or phone number below to learn more and optimize your machining operations.

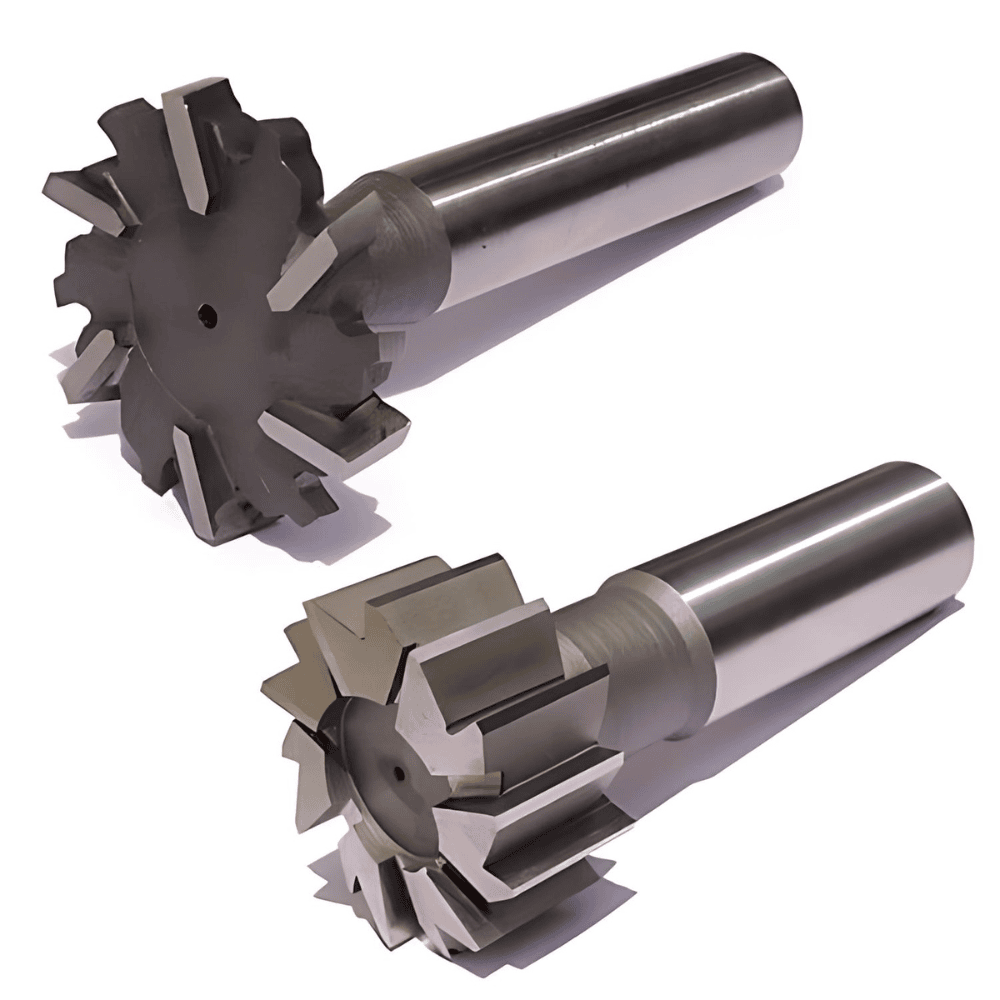

What Are Carbide Slot Cutters?

Carbide Slot Cutters are cutting tools used in machining processes to create slots or grooves in workpieces. Carbide Slot Cutters are known for their hardness, wear resistance, and ability to maintain sharp cutting edges even at high temperatures.

Features

- Longer tool life: lasts significantly longer than traditional high-speed steel (HSS) end mills, resulting in reduced tool replacement costs and downtime

- Increased productivity: the durability and wear resistance of carbide slot cutters allow for higher cutting speeds and feed rates, leading to faster machining processes

- Improved surface finish: produces smoother surface finishes on workpieces due to their ability to maintain sharp cutting edges

- Reduced machining time: with their high cutting speeds and feed rates, carbide slot cutters can help shorten overall machining cycle times

- Enhanced machining capabilities: enables the machining of hard materials such as hardened steels, stainless steels, and exotic alloys with greater efficiency and precision

Why Choose Carbide Slot Cutters From Us

- Superior quality: manufactured to the highest standards, ensuring consistent performance, precision, and durability

- Extensive selection: we offer a wide range of carbide slot cutters in various shapes, sizes, and configurations to meet the diverse needs of our customers’ machining applications

- Customization options: these can be customized to specific customer requirements, including special coatings, geometries, and lengths, providing tailored solutions for unique machining challenges

- Competitive pricing: we offer competitive pricing on our carbide slot cutters without compromising on quality, providing excellent value for our customers’ machining operations

Applications

- Construction

- Manufacturing

- Metalworking

- Woodworking

Supported Brands

Related Products

Inquire Now

Experience the superior precision and durability of Carbide Slot Cutters from Atek Precision Tools.

Contact us now using the contact form or phone number below to learn more and optimize your machining operations.

Contact Us

You’ve got questions, we’ve got answers!

Contact us now for product pricing or a free quote.

Call us for a free quote today!

(049) 544-0520

(+63) 917 327 6168