Imagine slashing production time while maintaining impeccable quality. Stick around as we dive into the 10 best cutting tools for automotive that could be game-changers for your operations.

These tools are not just high-precision; they’re investments that pay off in every perfectly cut component.

Don’t just take our word for it—these cutting tools have consistently delivered top-notch performance in some of the most demanding automotive manufacturing environments.

Curious about which tools can transform your production line? Read on…

Related post: How to choose the best cutting tools

Table of Contents

Why Cutting Tools are Essential in the Automotive Industry

Imagine trying to build a car without the right cutting tools—it’s like trying to cook a gourmet meal without a sharp knife!

In the automotive industry, cutting tools are the unsung heroes that ensure every part fits perfectly and functions flawlessly. Whether you’re dealing with engine components, body panels, or intricate interior details, the precision of your cutting tools directly impacts the quality of your final product.

These cutting tools enable you to achieve the exact specifications needed for each part, ensuring that everything works together seamlessly. Without them, production would be slower, less efficient, and ultimately more costly.

Top 10 Cutting Tools for Automotive Industry

Here are the best cutting tools for the automotive industry.

1. Carbide Cutting Tools

Carbide Cutting Tools are known for their exceptional hardness and resistance to wear. They can handle high-speed cutting operations without losing their edge.

These tools are perfect for machining hard materials like steel and cast irons, making them indispensable in engine part manufacturing.

The biggest advantage of carbide tools is their durability and ability to maintain precision at high speeds. However, they can be more expensive upfront compared to other materials.

2. Diamond Cutting Tools

Diamond Cutting Tools offer unmatched hardness and wear resistance. They provide superior surface finishes and are highly effective for high-precision tasks.

Ideal for cutting non-ferrous materials like aluminum and copper, as well as composites used in automotive interiors.

While diamond tools offer excellent performance and longevity, they are also among the most expensive cutting tools available.

3. High-Speed Steel (HSS) Cutting Tools

HSS Cutting Tools are versatile and can withstand higher temperatures without losing their hardness, making them suitable for a wide range of cutting applications.

Commonly used for drilling, milling, and turning operations, especially on softer materials like aluminum and mild steel.

HSS tools are more affordable and easier to re-sharpen, but they wear out faster than carbide or diamond tools.

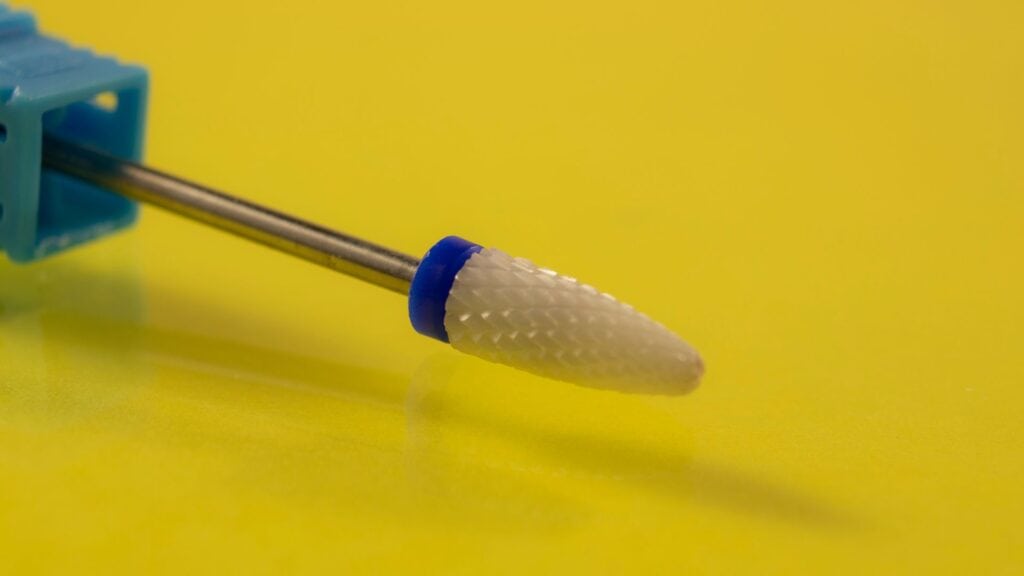

4. Ceramic Cutting Tools

Ceramic Cutting Tools are known for their high-temperature resistance and hardness. They are excellent for high-speed machining.

Ceramic cutting tools are perfect for cutting hard materials like cast iron and superalloys, often used in engine components.

Ceramic cutting tools offer excellent wear resistance but are more brittle and can break under heavy loads.

5. Cubic Boron Nitride (CBN) Cutting Tools

CBN Cutting Tools are second only to diamond in hardness and are highly wear-resistant. They perform exceptionally well in high-speed cutting operations.

CBN tools Ideal for machining hardened steels and other tough materials used in powertrain and transmission components.

CBN cutting tools provide excellent performance but come at a higher cost, making them a significant investment.

6. Polycrystalline Diamond (PCD) Cutting Tools

PCD Cutting Tools combine the hardness of diamond with enhanced toughness. They offer superior surface finishes and long tool life.

PCD tools are perfect for cutting abrasive materials, composites, and non-ferrous metals used in automotive body panels and interiors.

PCD cutting tools offer excellent longevity and surface finish but are among the most expensive options available.

7. Coated Carbide Tools

Coated Carbide Tools have a layer of wear-resistant material that enhances their durability and performance. Common coatings include titanium nitride (TiN) and aluminum oxide (Al2O3).

Coated carbide tools are suitable for a variety of applications, including drilling, milling, and turning of both ferrous and non-ferrous materials.

Coated carbide extends tool life and improves performance, but these tools can be more expensive than uncoated alternatives.

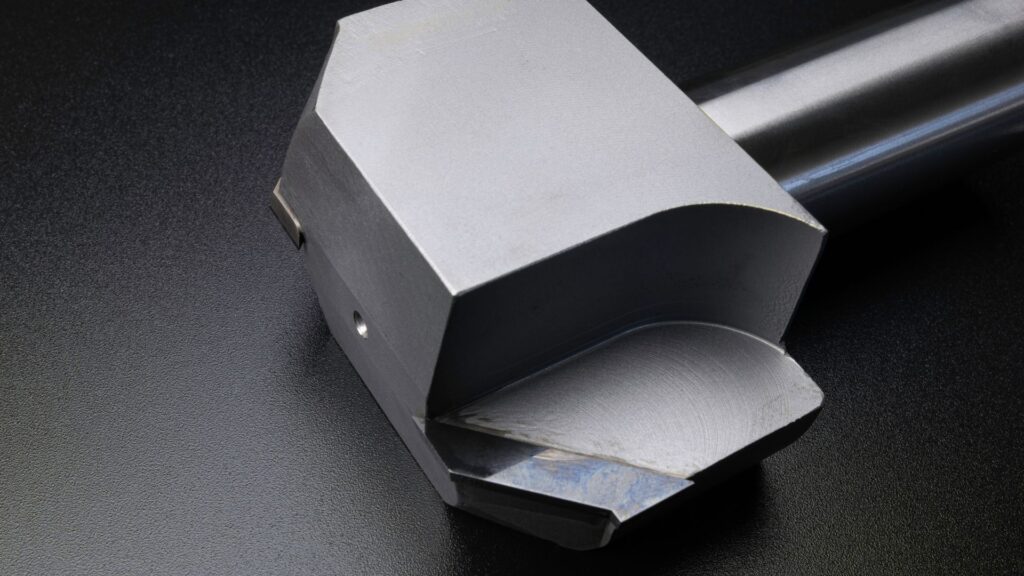

8. Indexable Cutting Tools

Indexable Cutting Tools feature replaceable inserts that can be rotated or replaced when worn, minimizing downtime and cost.

Indexable tools are widely used in turning, milling, and drilling operations, especially for high-volume production runs.

Indexable cutting tools are cost-effective and easy to maintain, but the initial setup can be more complex.

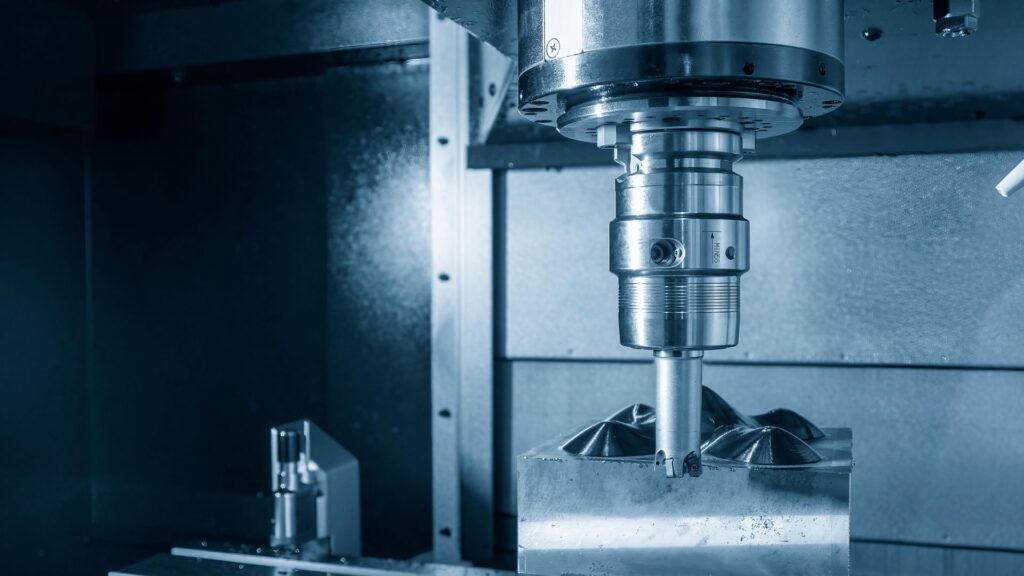

9. Solid Carbide End Mills

Solid Carbide End Mills are known for their rigidity and precision. They are capable of high-speed cutting and offer excellent surface finishes.

Solid carbide end mills are ideal for milling operations, particularly in the production of molds, dies, and precision components.

Solid carbide end mills provide excellent performance but can be costly and more prone to chipping under heavy loads.

10. Reamers and Boring Tools

Reamers and Boring Tools are designed for precision hole-making and finishing operations. They provide tight tolerances and smooth finishes.

Reamers and boring tools are essential for producing high-precision holes in engine blocks, transmission components, and other critical parts.

Reamers and boring tools offer unparalleled precision but require careful handling and maintenance to avoid damage.

FAQ

-

What are the common signs that a cutting tool needs to be replaced?

Common signs that a cutting tool needs replacement include visible wear and tear, such as dull edges, chips, or cracks. Additionally, if you notice a decline in cutting performance, increased vibration, or poor surface finish on the workpiece, it’s time to replace the tool.

-

How do I choose the right cutting fluid for my cutting tools?

Choosing the right cutting fluid depends on the material you’re cutting and the type of operation. For example, water-soluble coolants are often used for general machining of ferrous metals, while oil-based coolants are better for non-ferrous metals and heavy-duty operations. Always refer to the tool manufacturer’s recommendations for the best results.

-

Can improper storage affect the performance of cutting tools?

Yes, improper storage can significantly affect the performance and lifespan of cutting tools. Storing tools in a damp or dirty environment can lead to rust and corrosion. Always keep your tools in a clean, dry place, preferably in a designated storage cabinet or rack.

-

How often should cutting tools be inspected?

Cutting tools should be inspected regularly, ideally before and after each use. A more thorough inspection should be conducted weekly to check for any signs of wear or damage. Keeping a schedule for these inspections can help in timely maintenance and replacement, ensuring consistent performance.

Conclusion

So, what’s the takeaway? Investing in high-quality cutting tools is not just about keeping your production line running smoothly; it’s about ensuring that every part you produce meets the highest standards of quality. This is crucial in an industry where precision is key and errors can be costly.